Faster and smarter cnc nesting unit line for kitchen cabinet making

Faster and smarter cnc nesting unit line for kitchen cabinet making

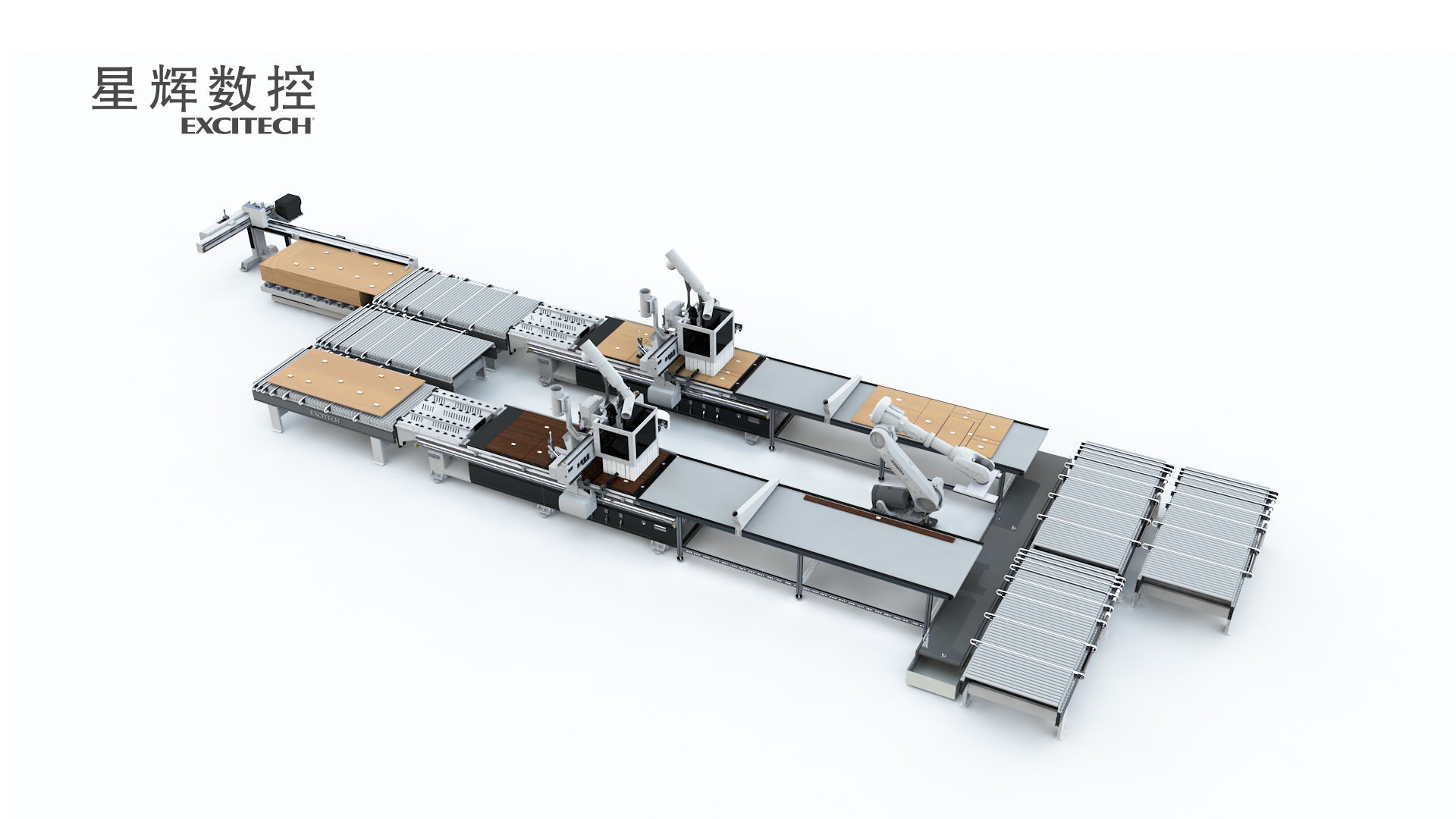

Professionally promote the informationization, intelligence and unmanned construction of the furniture industry. The combination is flexible, the process is changeable, and an automated production mode that meets the needs of the customer's entire plant is created. Combine CNC nesting machine with return conveyor to improve the automation level of the factory, get rid of the dependence on workers, and effectively improve management efficiency and production efficiency.

The nesting cell include E4 nesting machine, robot, return conveyor, cabinet box and the designing software. E4 nesting machine finish the work of automatic cutting, drilling and labeling, then robot automatically pick the panel, save the human labor and improve the working efficiency. The panel is transmitted through return conveyors, which is convenient for the follow-up work. The designing software is optional according to the customer's requirement.

Utilize the advantages of combining software and automation equipment, it can form mass production, thereby achieving automation production, reduce labor costs and increase production capacity.

Advantage:

- The first project successfully implemented by Chinese machinery manufacturer.

- No operator required for production rocedures. Labor cost and managing overheads are therefore greatly reduced, so is production error.

- Uninterruped production with automatic machines enables furniture makers to add extra shifts with minimum extra costs and concerns. The efficiency is also increased by at a least 25 % compared to manual operation.

- Smarter, more cost-efficient production, quicker delivery and better quality allow furniture makers for further expand production and sales, achieving higher return on capital and property.

- More individual products for end-users.

Japan SRA166L Robot

World Class Speed Robot

Robot motion makes minimum cycle times unbeatable. Light weight and high rigidity design makes high acceleration and minimum vibration.

Maximum speed on all axes reduces cycle time.

Improved productivity by these design.

Easy to use

Improved motor drive controls for accurate

positioning and repeatability.

Slim and compact design allows closer installation in less floor space.

Improved maintenance item. It can do easy parts replacement and inspection.

Energy saving

Power consumption reduced 15% from existing model by reducing the robot’s weight by 20% and using newest motor drive controls

Power Roller with translation machine: 3500*2700*900mm

- We provide 12 months warranty for the machine.

- Consumable parts will be replaced free during the warranty.

- Our engineer could provide technology support and training for you in your country, if necessary.

- Our engineer could service for you 24 hours online, by Whatsapp,Wechat,FACEBOOK, LINKEDIN,TIKTOK,cell phone hot line.

The cnc center is to be packed with plastic sheet for cleaning and damp proofing.

Fasten the cnc machine into the wood case for safety and against clashing.

Transport the wood case into the container.