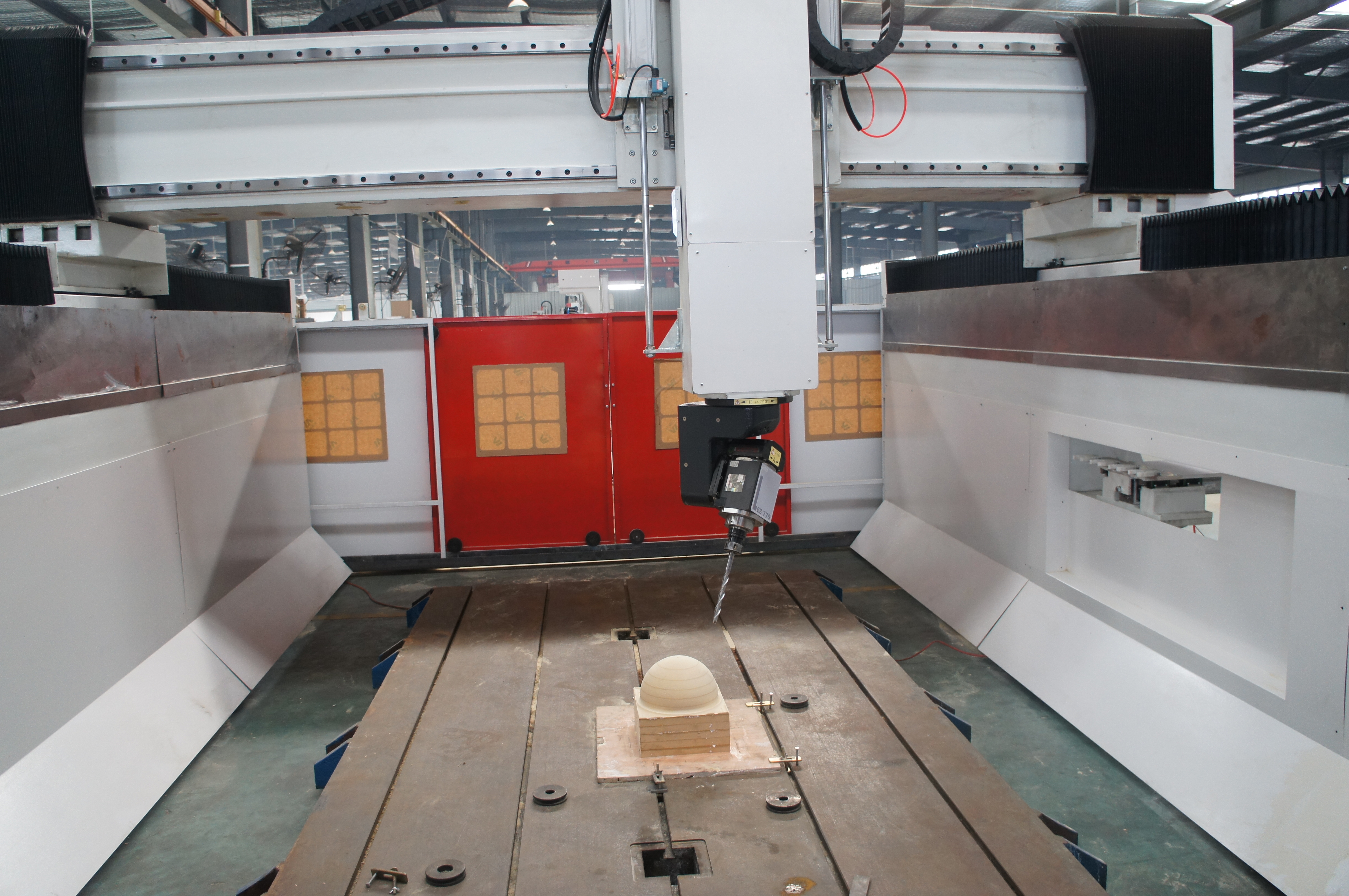

E10 Vantage tsib-axis machining chaw (muaj feem xyuam rau ntau cov ntaub ntawv)

E10 Vantage tsib-axis Machining Chaw

Tsib-axis engraving tshuab kuj tseem hu ua tsib-axis txuas engraving tshuab. Nws yog lub machining chaw nrog cov ntsiab lus siab thev naus laus zis thiab cov kev ntsuas siab tshwj xeeb siv rau machining complex curved nto. Cov twj siv, siab-precision cov cuab yeej siv kho mob thiab lwm yam kev lag luam muaj cov cawv pivotal. Tam sim no, tsib-axis qhov txuas CNC Machining Center yog tib txoj kev siv los ntawm cov impellers rotors, cov tshuab hluav taws xob hnyav, cov cav loj roj av, thiab lwm yam.

Lub tsib-axis Linkage EGRaving tshuab muaj cov yam ntxwv ntawm kev ua haujlwm siab thiab siab precision, thiab cov kev ua tiav tuaj yeem ua tiav hauv ib qho chaw ua haujlwm. Nws tuaj yeem hloov kho kev ua cov khoom siv ntawm cov niaj hnub xws li cov khoom pib thiab cov dav hlau txheej txheem. Muaj qhov sib txawv ntawm tsib-axis machining chaw thiab lub pentahedral machining chaw.

Coob tus neeg tsis paub qhov no thiab ua yuam kev lub pentahedron machining chaw ua tsib-axis machining chaw. Lub tsib-axis machining chaw muaj tsib tus ncej ntawm x, y, z, thiab c. Tus XYZ thiab AC Axes Daim Ntawv Tsib-Axis Linkage ua. Lub "pentahedron machining chaw" zoo ib yam li peb-axis chaw, tsuas yog tias nws tuaj yeem ua tsis tau tsib lub sijhawm, tab sis nws tsis tuaj yeem ua cov khoom tshwj xeeb zoo li cas, oblique txiav, thiab bevel txiav

Qhov tsis zoo txhais peb

Xeev-ntawm-cov-kos duab thiab chaw

Peb ntau yam ntawm kev yooj yim muaj yooj yim heev muaj nyob rau cov chaw tsim hluav taws xob zoo,Vaj Huam Sib Luag Rooj Tog Zov Khoom Ntau Lawm Cov Ntsiab Lus,Ntau qhov loj me 5-axis

Machining chaw,Vaj huam sib luag Saws,Taw tes-rau-point ua haujlwm chaw ua haujlwm thiab lwm yam Machineries muab fij rau woodworking thiab lwm cov ntawv thov tseem ceeb.

Zoo tsis tau outsourced-tag nrho cov txheej txheem tsim khoom yog meticulously thiab systematically tswj kom ua tiav qhov lav pom zoo thiab ua tau zoo.

•Cov khoom lag luam zoo nrog kev ua haujlwm siab ntau lawm

•Cov nqi qis dua li khaws tau nyiaj

•Lub peev xwm loj heev rau cov txiaj ntsig zoo dua

•Dramatically txo cov sij hawm

Peb ua kom yooj yim thiab ua kom zoo rau koj cov khoom lag luam.

Ntau yam kev hloov pauv, tsis muaj kev cuam tshuam ua haujlwm sib deev

Qhov chaw≥10 hli kev ua tiav.

Zoo heev txo cov khoom lag luam phem.

Kev ua kom tau zoo tus nqi nce ntxiv.

Ob npaug nyiaj ua haujlwm thiab tso zis.

Raws li cov khoom ua haujlwm ntws tawm los ua cov khoom tiav.

Kev tswj kev ntau lawm yog qhov yooj yim dua.

85% txo cov khoom lag luam tsis zoo 10 rau cov khoom me me 90±1% kev ua kom zoo dua 85% + automatized

- Peb muab 12 lub hlis lav rau lub tshuab.

- Cov khoom siv tau yuav raug hloov dawb thaum muaj kev tiv thaiv.

- Peb tus kws tshaj lij tuaj yeem muab kev txhawb nqa thev naus laus zis thiab kev qhia rau koj hauv koj lub tebchaws, yog tias tsim nyog.

- Peb cov kws ua haujlwm tuaj yeem pab rau koj 24 teev hauv online, los ntawm WhatsApp, WeChat, Facebook, LinkedIn, Cell Xov tooj kub kab.

TheCNC CENTER yuav tsum tau ntim nrog cov ntawv yas rau kev tu thiab cov ntawv pov thawj damping.

Ntsuas lub tshuab cnc rau hauv cov ntaub ntawv ntoo kom muaj kev nyab xeeb thiab tawm tsam kev sib tsoo.

Thauj cov ntoo ntoo rau hauv lub thawv.